8 Easy Facts About Well Water Filtration Explained

Table of ContentsFascination About Well Water FiltrationThe Well Water Filtration IdeasNot known Factual Statements About Well Water Filtration The Of Well Water Filtration

Pathogenic microorganisms are the tiny in the water that can trigger waterborne illness such as gastroenteritis, typhoid, dysentery, cholera, and giardiasis (well water filtration). Step 5 Filtration, The chlorinated worked out water after that streams into the Filtering Center as well as onto the filters for the last of the major system procedures used to deal with the drinking water.

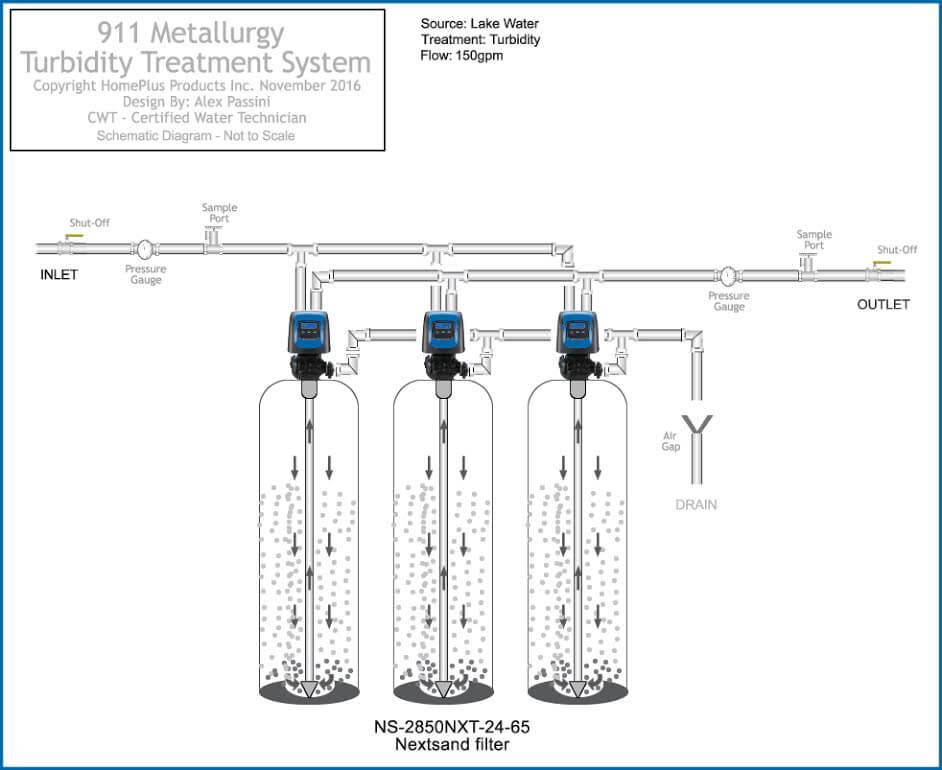

When the filters begin to get packed packed with fragments, the operators cleanse them using a procedure called. Drinkable water is run in reverse via the filters releasing the entrapped particulates that are collected in drain troughs. The backwash water is sent to the Backwash Recovery Pond and, after a settling procedure, the backwash water is gone back to the raw water settling fish pond for re-use.

Prior to the water leaves the clearwells under the water treatment plant chlorine is included a second time for post-disinfection. The added chlorine ensures that the water stays safe to consume also at the furthest reaches of the distribution system. Along with the chlorine, fluoride is included to our alcohol consumption water at the plant.

Well Water Filtration Fundamentals Explained

The United States Public Health and wellness Solution has established the optimal focus for fluoride in United States water to be in the range of 0. Dissolved fluoride-containing minerals are gauged year-round in the water of the Arkansas River.

The water treatment plants enough fluoride to increase that degree to. 9 components per million. The fluoride degree is gauged daily at the water therapy plant and regular monthly at the faucet to see to it it suffices to fulfill the focus recommended by United States Public Health And Wellness Solution (USPHS) (well water filtration).

The water is tested daily for various specifications by our water plant operators as well as by continuous internet monitoring by procedure instrumentation. Some of the water top quality parameters kept an eye on and also examined for are chlorine, turbidity, alkalinity, solidity, liquified oxygen, conductivity, as well as p, H. Values for parameters of the treated water modification with the time of year.

Coagulation When water gets in a treatment plant, the initial stage in the process is coagulation where chemicals are contributed to the supply of water to allow microparticles as well as little solids to stick together. Polyelectrolyte, ferrous sulfate, and also light weight aluminum sulfate are instances of chemicals made use of in the water therapy plant procedure to assist coagulation.

A Biased View of Well Water Filtration

Quality standards additionally need to be met as part of the regulative processes within water treatment plants. This consists of routine why not try here upkeep of the system by qualified designers. Flocculation As soon as water has been treated with the coagulation chemicals it gets in read this post here a container with large paddles. These mix the chemicals and also water with each other as well as enable the micro bits to create right into bigger items that are likely to stick, making the sedimentation procedure in water treatment much more effective.

During this final phase water is passed through a filter in a regulated way. Final Ideas on The Process of Water Filtration in Water Plants The water purification plant processes are essential to preserving a safe supply of water for public and business usage.

Industrial water treatment systems satisfy a selection of filtration as well as splitting up requirements. They can vary from reasonably portable and simple to complex, multiunit processes that serve a variety of applications. If you're brand-new to water therapy, you may be asking Because industrial water treatment is a complicated household of modern technologies and also systems, this write-up will certainly concentrate on offering a top-level introduction of the technologies that find are commonly utilized and sum up exactly how they function, assisting you to much better comprehend the very best possible solutions for your facility.

The Greatest Guide To Well Water Filtration

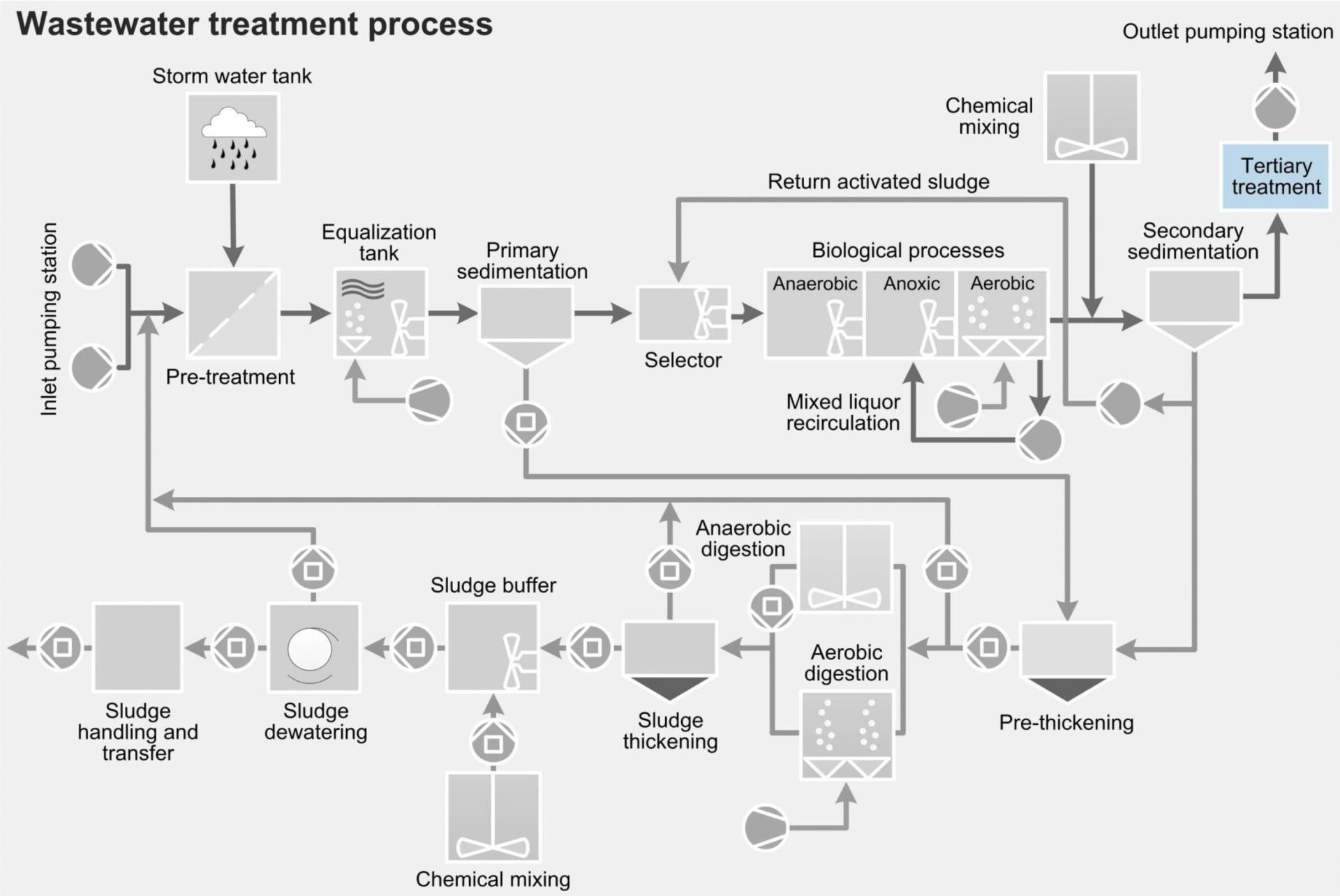

That claimed, each system will differ depending upon the facility's demands as well as numerous of the innovations that comprise these systems can be similar. In general, some of the most-needed industrial water treatment systems generally consist of: Raw water therapy systems Central heating boiler feed water therapy systems Cooling down tower water therapy systems Wastewater treatment systems The modern technologies picked and in what order they show up in each water treatment system will certainly vary depending on the pollutants that need to be gotten rid of, however it is feasible to narrow down what you could see in these four usual industrial therapy systems.

The stream is filtered with a gravity sand filter to trap any type of tiny particles that did not clear up out. If biological contamination and/or water potability is a worry, the water may then be decontaminated to remove any virus. Sanitation might be completed through the application of chemical anti-bacterials (e.

In IX softening, a stream is directed through a strong acid cation resin that is "billed" with salt; as the water moves through, the resin catches the hardness-causing calcium or magnesium ions, while releasing the sodium ions into the stream. Adhering to treatment, the water is pumped or otherwise routed for usage somewhere else in the center.